Balancing the Scales of the Geothermal Resource

December 20, 2018

Leveraging Existing O&G Wells will Reduce Drilling Costs by 50%

January 1, 2019Fluid Hammer Could Reduce Costs of Geothermal Wells

Fluid-Powered Downhole Hammer Has Potential to Significantly Reduce the Cost of Deep Geothermal Borehole

Geothermal waters usually occur at relatively greater depths and in harder rock formations than in the case of sedimentary-based hydrocarbon reservoirs. Such conditions cause quite a long and challenging drilling process. The rate of penetration as well as tool life significantly decrease in hard rock formations and put an immense impact on the investment costs.

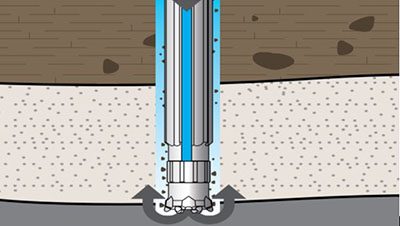

Over the years, Down-The-Hole (DTH) hammer technology has demonstrated high efficiency, especially in drilling shallow geothermal wells (< 400 m). In recent years, a significant amount of research has been invested in the development and application of this technology at much greater depths. DTH hammer method makes it possible to combine impact phenomenon with rotation, while the drilling rig allows controlling pressure in the borehole, torque, and weight on the bit. In shallow boreholes, an air-powered hammer is most commonly applied, whereas, in deeper wells, such a method loses its effectiveness, especially when water-bearing layers are being encountered. The new hammer drilling technology, commercialized by the Wassara company, uses water, instead of air, as a drilling fluid. It allows drilling much deeper holes, even within water-rich rock formations and provides effective removal of cuttings and their elevation to the surface. The decrease in investment costs using the water-powered DTH hammer method is caused, among other, by increased drilling speed, but also lower wear of the drilling tool in comparison with air-powered hammers, a much better quality of the hole and fewer costs of drilling equipment.

The biggest disadvantage of water-powered DTH is a limitation of drilling fluid used to clean water only. Any solid particles, which may come in contact with the device, cause its fast wear and erosion. Due to this reason, great emphasis is placed on improving the recycling technology of the drilling mud during drilling. Current technology does not yet allow for the introduction of any drilling mud additives. Research on the improvements of hammer drilling technology is currently being carried out in many research institutions around the world including e.g. Germany, Norway, and France.

Recent case scenarios of DTH water- and air-powered hammer application in deep drilling projects worldwide have proven the applicability of such method on a larger scale in many geothermal boreholes. A deep geothermal well in South Korea drilled with the DTH hammer method in hard granite using an 8″ tool allowed for drilling speed of 15 m/h at the first 1.5 km and 10 m/h to a depth of 4.5 km. The Finnish company St1 project in Espoo, near Helsinki, drilled a geothermal well to a depth of 4.5 km using an air-powered DTH hammer, followed by a combination of a traditional rotary method with a DTH hammer method to a depth of 6.4 km. It is currently the deepest geothermal well in Finland and one of the deepest geothermal wells in Europe.

For more on the advancements of drilling technology and our geothermal industry, check back for more #GeothermalFactsandStats

Author: Michal Kruszewski

Sources: Wassara and St1 Deep Heat Ltd.

#Geothermal #lovegeothermal #renewableenergy