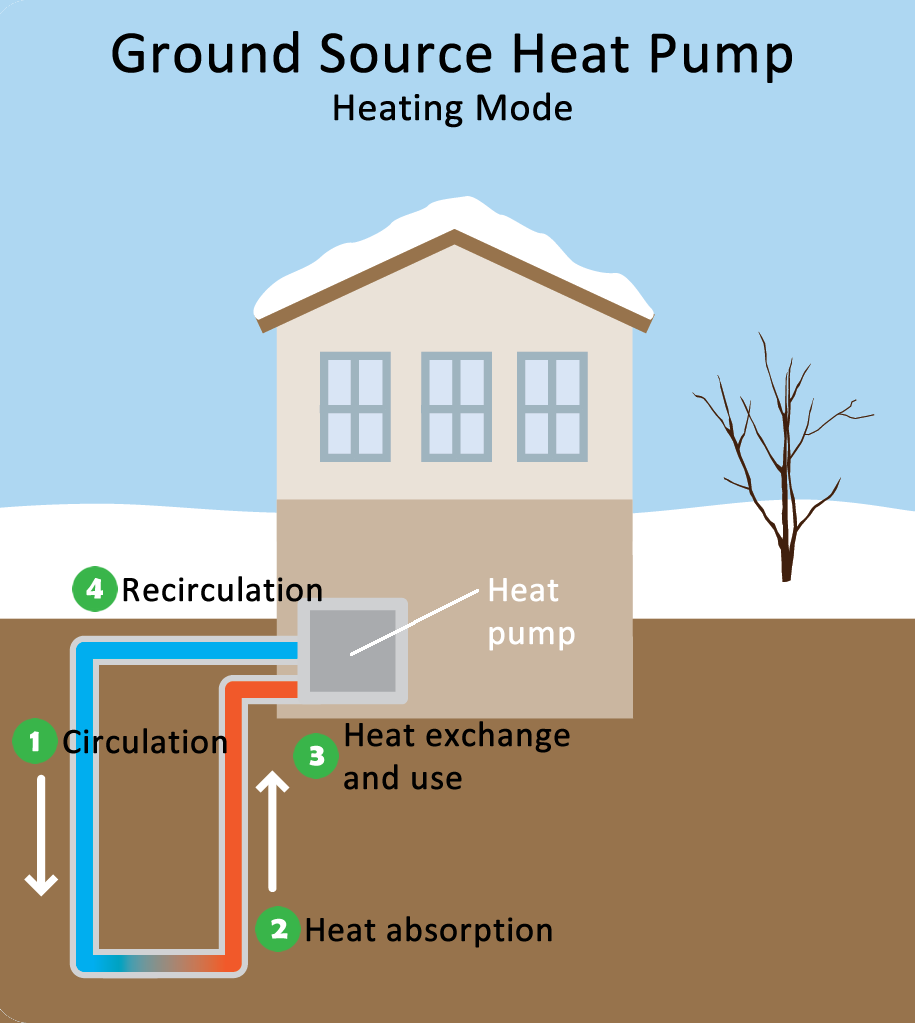

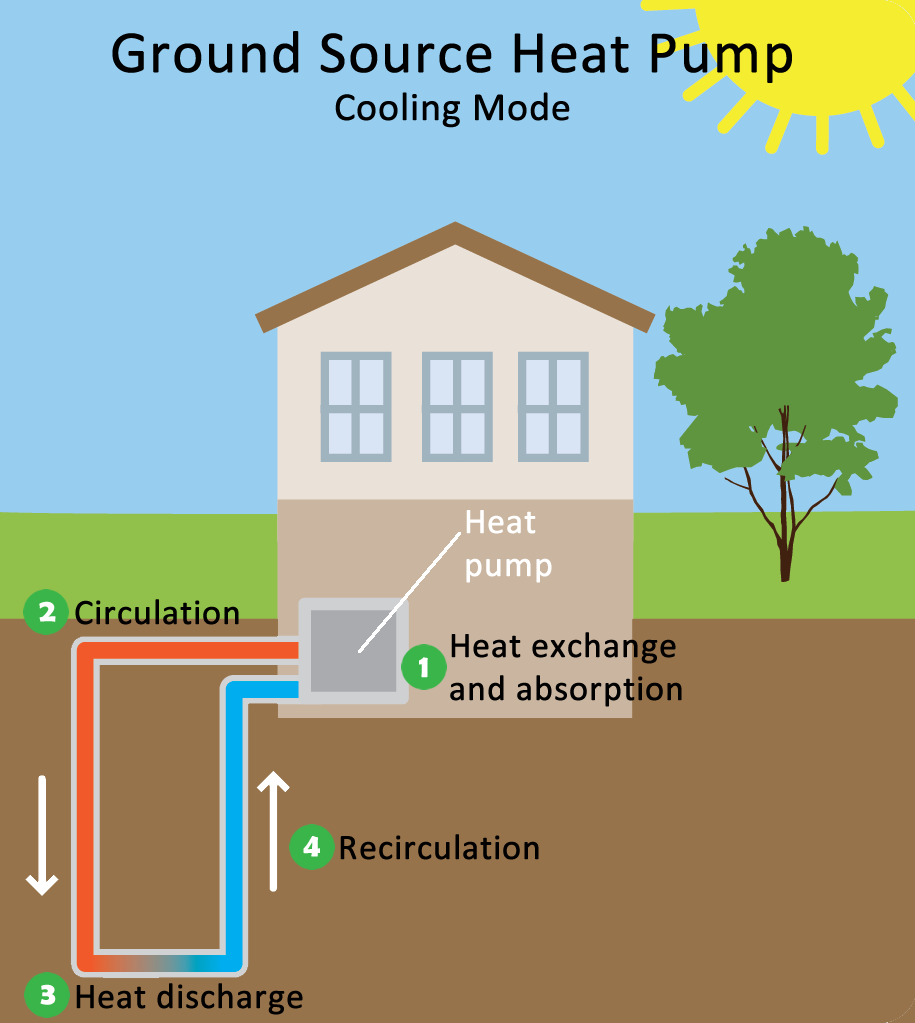

Borehole Heat Exchangers (BHE) are being increasingly utilized for heat purposes in public as well as communal infrastructure at depths ranging from 100 to 400 m. BHE technology allows for heat exchange between an underground rock mass and heat carrier, circulating in the closed-loop system between the surface and the reservoir. BHE systems are able to provide heat in winter seasons and cooling in summer months. For many installations, more than one borehole is used for energy exchange with the underground rock mass. BHE systems can supply heat in a direct manner (i.e. passive), especially in deeper wells or with so-called ground source heat pumps (i.e. active), when harvesting low-enthalpy heat resources.

Fig. 1. Heating mode of Ground Source Heat Pump during winter months (source: www.epa.gov)

Fig. 1. Heating mode of Ground Source Heat Pump during winter months (source: www.epa.gov)

Fig. 2. Cooling mode of Ground Source Heat Pump during summer months (source: www.epa.gov)

Fig. 2. Cooling mode of Ground Source Heat Pump during summer months (source: www.epa.gov)

BHE can be drilled as vertical or directional wells. Typical construction designs of BHE include single U-pipe, multi (e.g. double, triple) U-pipe, coaxial type (mainly utilized for medium to deep BHE), helical type, BHE in piles as well as BHE with direct heat carrier evaporation. The most significant parameters controlling the thermal extraction output of such systems are the heat conductivity and heat capacity of the ground as well as BHE construction type and completion (i.e. grout and pipe material type used). BHE-based installation is particularly efficient in combination with solar installations. The geological structure, as well as the rock thermal properties, vary from place to place. It is thus important for the planning of a geothermal installation based on BHE to take the variability of the geological properties of the rock mass into account. Some of the ideal placement sites for BHE are characterized by a uniform low to medium hydraulic conductivity. Areas with highly permeable karst aquifers or fractured hard rock aquifers are less favorable due to potential technical challenges with drilling operations and casing setting. Drilling is often troubled by drilling fluid and grout losses into the adjacent rock formations and can result in groundwater contamination or induce swelling of evaporites.

BHE’s can be reconstructed, as coaxial-type systems, from deep and temporarily abandoned wells which were originally purposed for crude oil or natural gas production. Such installations significantly decrease drilling costs however the reconstruction procedure may turn out to be technically complex and expensive. This is mainly due to the high market price of the inner pipe material having a low heat transfer coefficient.

Fig. 3. Drilling of shallow BHE system (source: www.energyclever.com)

Fig. 3. Drilling of shallow BHE system (source: www.energyclever.com)

For more information on Borehole Heat Exchangers, Ground Source Heat Pumps or anything for that matter, continue reading our #GeothermalFactsandStats blog here and follow us on all major social media platforms.

Sources:

Ingrid Stober and Kurt Bucher, Geothermal Energy from Theoretical Models to Exploration and Development, ISBN 978-3-642-13351-0, Springer, (2013).

Śliwa T., Jaszczur M., Kruszewski M., Sapińska-Śliwa A., Bieda A., Kowalski T., Złotkowski A., A Study of Hydraulic Characteristic for Borehole Heat Exchangers, AGH Drilling, Oil, Gas, Vol. 34, no. 1, p. 465-492, 2017

Author: Michal Kruszewski