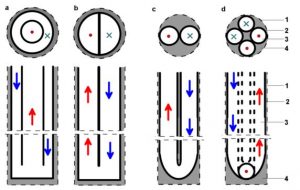

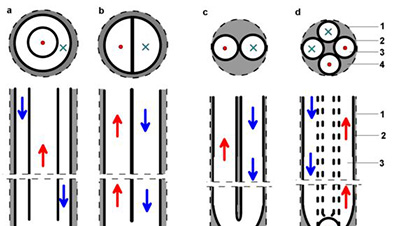

One of the ways to extract geothermal heat from the Earth’s crust is Deep Borehole Heat Exchangers (DBHE). These can be either drilled especially for heat extraction or, what is more cost effective, reconstructed from already existing, negative or abandoned oil or natural gas wells. Borehole heat exchangers allow the exchange of geothermal heat between rock formation and heat carrier, circulating in the closed-loop system between the surface and an underground reservoir. The heat can be supplied directly or indirectly using heat pump systems. In many depleted boreholes, exploiting underground geothermal waters is either impossible or technically complex, therefore potential reconstruction for a borehole heat exchanger might be the only solution that allows for utilizing geothermal heat. Countries such as Poland, Norway or Canada have considerable potential to implement DBHE technology, mainly due to a large number of deep and abandoned petroleum wells, which might be located in close vicinity to the potential heat recipients.

During reconstruction operations of an already existing well, the inner column is the most important feature, which in large part determines the overall success of the DBHE investment. Other properties include already existing well construction and characteristic of an underground rock mass. Vacuum Insulated Tubing (VIT) technology, widely used in the offshore industry, might be one of the potential technologies to efficiently extract geothermal heat from the DBHE installations. VIT constitutes two coaxial steel pipes, where air between them is evacuated using a vacuum pump. VIT technology decreases heat transfer between the inner coaxial column and the existing well construction. Such insulated tubes are implemented in order to eliminate the high heat exchange caused by convection, radiation, and conduction. These features can lengthen the life expectancy of the DBHE systems, increase efficiency and decrease costs without having any negative impact on the environment. The VIT demonstrated thermal conductivity coefficient varied from 0.006 to 0.0008 W/(m·K), whereas for conventional steel pipes this value amounts to 40 W/(m·K).

Source: Tomasz Śliwa, Michał Kruszewski, Alireza Zare, Mohsen Assadi, Aneta Sapińska-Śliwa, Potential application of vacuum insulated tubing for deep borehole heat exchangers Geothermics, Volume 75, September 2018, Pages 58-67)

Figure 1: Potential construction designs of BHE and DBHE systems (a – coaxial heat exchanger, b – demi-type heat exchanger, c – heat exchanger with single U-pipe, d – heat exchanger with double U-pipe, 1–wall of the borehole, 2–heat exchanger pipe, 3–heat carrier, 4–sealant) (source: Tomasz Śliwa, Michał Kruszewski, Alireza Zare, Mohsen Assadi, Aneta Sapińska-Śliwa, Potential application of vacuum insulated tubing for deep borehole heat exchangers, Geothermics, Volume 75, September 2018, Pages 58-67)

Figure 2: Drilling operation for shallow borehole heat exchangers – source: https://www.weishaupt.de/en/press/bild-datenbank/waermepumpen/erdsondenbohrungen-sowie-die-einrichtung-von-brunnenanlagen-erfolgen-durch-das-zur-weishaupt-gruppe-gehoerende-bohrunternehmen-baugrund-sued

For more #GeothermalFactsandStats about DBHE and VIT, keep checking out our blog here and follow all us on all the major social media platforms!

Author: Michal Kruszewski

#geothermal #renewableenergy #drilling #VacuumInsulatedTubing #DeepBoreholeHeatExchangers #heatexchangers