The benefits of geothermal development have undoubtedly increased within recent years as new technologies are introduced. If you’ve been following our #GeothermalFactsandStats campaign, you would’ve learned about the purpose and stages of producing an Environmental and Social Impact Assessment (ESIA). In this post, we will address some of the issues and proposals for mitigation found in a geothermal ESIA document.

Potential risks

Drilling for the geothermal resource and power plant implementation have been known to raise uncertainty because of the associated environmental and social effects. Water quality and supply, air emissions, land-use and induced seismicity caused by EGS are among the major concerns. Water is required for both traditional geothermal systems and EGS throughout the life-cycle of a power plant. For traditional projects, water available at the resource is most often used for energy generation during plant operations. Depending on the technology employed for electricity generation, production can lower the water table over time, affecting surrounding areas. In addition to energy generation purposes, water is also used for cooling the working fluid in the plant.

Water is used in EGS for drilling and constructing wells, pipelines, plant infrastructure, stimulating injection wells and operating the power plant. Although water extracted from the formation is reinjected after use, some are lost to the formation. Lost water must be made up of alternative water sources to maintain a constant pressure in the system and for operation. A risk to water quantity is also accompanied by risk to water quality. Additives may be used to reduce solid deposition on equipment and casings during drilling. While the risk of aquifer contamination exists for both conventional geothermal systems and Enhanced Geothermal Systems (EGS), dissolved solids increase significantly with an increase in temperature. This heightens the magnitude of contamination if a leak occurs within an EGS. Water from high-temperature formations are often characterized by relatively high amounts of chlorides, silica, boron, and arsenic. Hot water pumped from underground reservoirs often contains high levels of sulfur, salt, and other minerals. Open-loop systems emit carbon dioxide, ammonia, methane, and boron with hydrogen sulfide being the most common emission.

With regards to water supply, geothermal plants require a constant flow of water – in some cases, a natural source is used. These sources may include rivers, lakes or underground wells. If more water is taken from these sources than the rate of replenishment, this can pose problems not only for the power plant but for the source and any aquatic ecosystems which exist. Other natural factors must be considered. For countries located in tropical climates, there must be some level of accountability for these sources during the dry season when water levels and flow rate decrease. Likewise, in temperate climates, should water sources become frozen during winter.

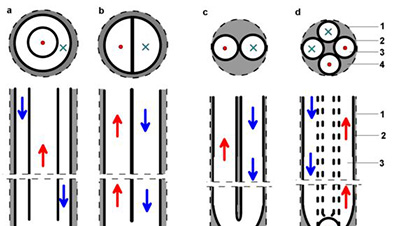

EGS has been linked to induced seismicity from drilling and hydro-fracking. Vibrations at the surface result during fracturing as the hot rock collapses on itself and slips. What’s more? Water use poses an even bigger issue than surface vibrations. EGS sites utilize water for building and operation. Water measuring up 2 million gallons or more is first used to prop open cracked rock. As the rock becomes unsealed, the volume of nearby reservoirs reduces significantly, lowering the water table. This is only counteracted if millions of gallons of water are added to the surface.

Mitigation

Countries such as the United States have imposed strategies to mitigate resource risk. Securing an adequate area of land to ensure the availability of sufficient productive acreage and to minimize the risk of interference from any competing development. Developing and continually modifying the conceptual hydrologic model of the geothermal field, to guide drilling and field development activities. Developing fields in an incremental way by beginning with a project of relatively modest size, and gradually building up a body of understanding about the resource and how to exploit it.

If a production history exists (empirical data from early development), forecasts of reservoir performance using a well-calibrated numerical reservoir model are conducted and innovative operational strategies to optimize field output and minimize operations and maintenance (O&M) costs are developed. For conventional geothermal systems, care in site selection can mitigate much of the risk to nearby aquifers. Additionally, solids can be collected and removed; with proper management, surface impacts from waste generation can be minimized.

Where EGS systems are implemented, rock movements can be monitored and controlled. By planting seismometers around the rock to be fractured, engineers can monitor the spreading of cracks. Since water pumps control the cracking and slipping, turning off the water can stop cracking. With good planning, no large earthquakes will occur. Developers can check regional geological maps to locate large fault zones. Additionally, developers can measure seismicity at sites before work begins in the area. This would prevent constructing an EGS site near such fault types where high-pressure pumping could disturb the fault and increase seismic risks.

Water circulating through hot rock may pick up arsenic and other poisonous substances. To reduce the risk of aquifer contamination, leaking at the surface or leaking into underground freshwater for EGS, mitigations can be imposed through well design. Engineers keep the circulating water contained. On the surface, it flows through pipes which lead into the wells, and when the water flows through the cracked rock, a jacket of uncracked rock serves as insulation. Produced fluid is also reinjected, solids are collected, and chemical treatment may be applied to address precipitation of dissolved solids after heat transfer.

Want more #GeothermalFactsandStats? Click through our recent blog posts here! And keep following us on all our social media platforms!

Author: Elizabeth Bullock

Sources:

http://www.geothermalcommunities.eu/assets/elearning/8.13.geothermal_water_assessment_use.pdf

https://orkustofnun.is/gogn/unu-gtp-sc/UNU-GTP-SC-18-41.pdf

https://www.energy.gov/sites/prod/files/2014/02/f7/geothermal_water_use.pdf

Photo credit: https://www.equinor.com/en/how-and-why/climate-change/geothermal-energy.html