It is anticipated that the utilization of geothermal resources for renewable energy production will continue to grow globally. Since the cost of drilling and well construction constitutes a considerable share of the total cost of the geothermal installations, development and evaluation of low-cost alternatives are crucial for expansion of the industry. Slimhole drilling technology, a low-cost alternative for conventional and wide-diameter exploration wells, can play an important role in reservoir assessment, especially in new areas. Besides the advantage of lower cost, slimhole technology reduces the environmental impact of field exploration and resource assessment.

Fig. 1. Rig (100 t) drilling a slim hole to 1500 m with 7″ production casing and a 4-1⁄2″ slotted liner (Thorhallsson and Gunnsteinsson 2012)

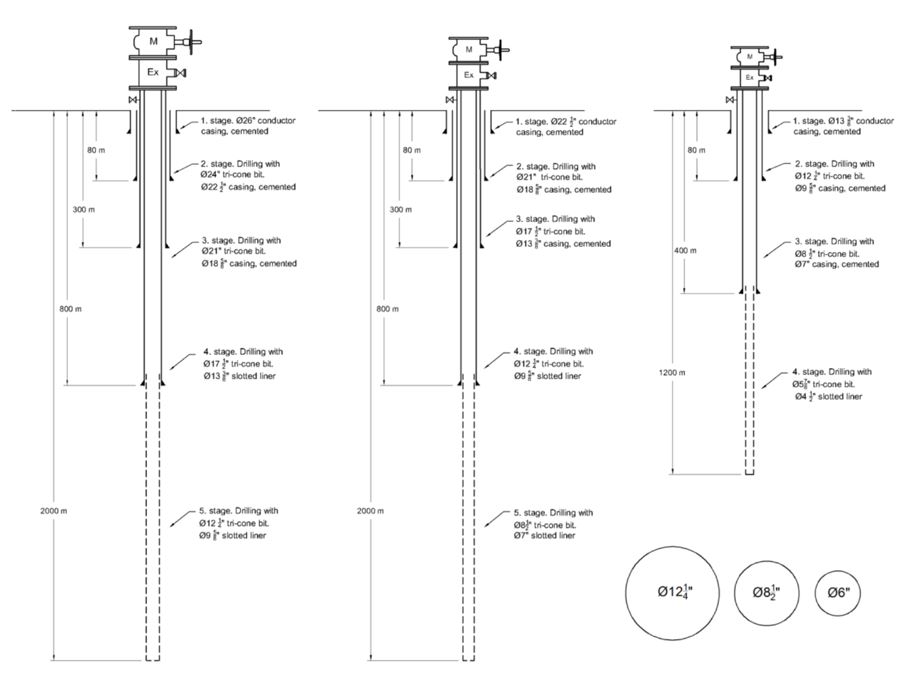

Wells with a diameter less than six inches are defined as slimholes. They are less costly than normal-size holes due to reduced cost needed for drilling crew, rigs, cementing, drilling fluids, casing, and tubing. Drilling production-size holes can put a large expense during first stages of the project and if well turns out to be non-productive or low in temperature, it can lead to long periods of debt for a potential investor. In other words, very expensive geothermal wells are being drilled with no reservoir knowledge and very high financial risk. A Sandia National Laboratories report on slimhole drilling finds the intermediate cost of drilling slim wells is around 60% of the large well’s overall costs to equivalent depth, where some other sources imply even 25 to 35%. On this account, an investor can drill three to four slim wells for the cost of one large-size well for better geothermal reservoir evaluation. Such a solution can be easily applied in remote areas, where helicopter-portable rigs can be used.

The technology used in the geothermal industry is adopted directly from the O&G industry with minor modifications. Geothermal reservoir conditions are much different from oil and gas reservoirs, where steam/water at high temperature has to be produced in large quantities and thus large casing diameters and open hole sections are required for large scale utilization. Wells smaller in diameter can, however, be used for exploration drilling to confirm the resource. Slimhole technology is adopted from already established techniques from deep-water wells, mineral exploration, and geotechnical investigations. Depending on the geological characteristic of area different methods of slimhole drilling can be used. Wireline coring method has a lower environmental impact and drilling costs (with the core barrel can be used as casing string) than conventional rotary drilling method. On the other hand, the rotary method provides faster drilling and there are no depth limitations as during wire-line coring technique.

Slim wells can be utilized to measure geothermal gradients and pursue flow tests in not yet assessed areas. In reservoirs with low-permeability, the size of the hole has no significant impact on total flow. However, in high-permeability reservoirs, there might be some restrictions and higher friction losses, limiting total flow. A large amount of research in Japan and the US confirm that flow testing in slim wells turned out to be equally informative as these in large size wells. Thus, data produced from slimholes can provide a good prediction of reservoir productivity.

For more #GeothermalFactsandStats continue reading our blog and follow us across all major social media platforms.

Fig. 2. Comparison of casing programs for three well types. The large and regular are very common in geothermal areas up to date (Thorhallsson and Gunnsteinsson 2012)

Author: Michal Kruszewski

Sources:

Sverrir Thorhallsson and Stefan Sturla Gunnsteinsson, SLIM WELLS FOR GEOTHERMAL EXPLORATION, Presented At “Short Course on Geothermal Development And Geothermal Wells”, Organized By UNU-GTP And Lageo, In Santa Tecla, El Salvador, March 11-17, 2012

Michał Kruszewski, Sverrir Thorhallsson, Mohsen Assadi, Tomasz Śliwa, SLIMHOLE WELL CASING DESIGN FOR HIGH-TEMPERATURE GEOTHERMAL EXPLORATION AND RESERVOIR ASSESSMENT, AGH DRILLING, OIL, GAS Vol. 34, No. 2, 2017

#geothermal #slimhole #exploration #casing #casingdesign #hightemperature #reservoirassessment