One of the most critical operations while drilling boreholes to explore geothermal resources is the primary cementing. Cement blend, placed behind the steel casing string, have to not only withstand high-temperature gradients during placement, drilling, and geothermal fluid production but also resist cyclic loading during operations such as well stimulation, production kick-off or an undesirable event of well quenching with cold water. The conventional cement mixture based on Portland cement G or H class with 40% of silica flour has proven performance in conventional geothermal wells, where temperatures of produced fluids are below 350°C. The Ordinary Portland Cement (OPC) experiences strength retrogression as early as at 110°C, after which a rapid decrease of compressive strength and chemical resistance and increase in permeability is seen. In order to provide better thermal as well as corrosion resistance, especially in wells exploring resources above 350°C, improved cement mixtures are necessary. These blends must ensure higher ductility of hardened cement and might include non-Portland mixtures such as geopolymers or calcium phosphate sealing systems, lower density cement blends (e.g. foam cement) that proven higher cement ductility and lower probability of rock fracturing during cementing operations. The Venelle-2 well can be regarded as a successful use of non-Portland cement blend in geothermal well exploring supercritical resources. The cement mixture, designed for boreholes experiencing well temperatures in excess of 450°C, was used for all 7” sections of the well and also for the temporary abandonment job and up to now, there have been no registered problems related to the cement job quality. Another option includes adding plasticizers such as liquid latex to the conventional cement mixtures in order to create a more ductile sealing system.

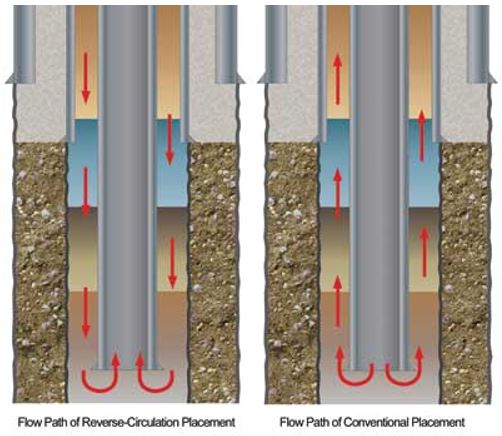

Not only cement mixtures but also improvements of cement placement method for primary as well as remedial cementing jobs are necessary. Stage cementing methods often do not satisfy conditions of wells exploring geothermal resources, which are drilled very often in zones of partial to total losses of drilling fluid and in extremely high thermal gradients. The most suitable cementing method has to allow for continuous cementing to achieve full sealing of any existing and newly created fractures during cementing and ensure a good bond between casing and rock formations. It is usual to pump much more excess cement in a high-temperature geothermal well than it is required for a petroleum or a natural gas well. Common cementing procedures include stage, inner string, reverse circulation, tie-back, lightweight cementing, and annulus packer method. In recently drilled high-temperature wells, where cementing jobs at greater depths, possibly in loss circulation zones, is needed, the reverse circulation cementing method is being more commonly applied (e.g. the IDDP-1 and IDDP-2 wells in Iceland or the Habanero-4 well in Australia).

Conventional and reverse primary cementing operation (source: National Energy Technology Laboratory, US Department of Energy)

For more #GeothermalFactsandStats, follow our posts on all major social media platforms and check back for weekly updates to our blog!

Sources: Kruszewski and Wittig, Geothermal Energy (2018) 6:28 DOI:10.1186/s40517-018-0113-4

Author: Michal Kruszewski

#Geothermal #hightemperature, #cementing #flow #wellboreintegrity