The most important parameters obtained during drilling of any kind of geothermal well are temperature and pressure measurements. Currently available off-the-shelf logging equipment allow recording temperatures with a maximum of 350°C and approximately 4 hours of downhole operation time. A reliable system of temperature recording at extreme temperatures for any condition of a geothermal well is however not yet developed. As of today, several research projects, most commonly from EU-founded initiatives, focused on developing logging technologies for geothermal wells experiencing extreme temperatures. One of these projects, HITI (High-Temperature Instruments for supercritical geothermal reservoir characterization and exploitation) developed a temperature logging tool for well conditions reaching the critical point of pure water (Ásmundsson et al. 2014). Another project was initiated during the Venelle-2 drilling venture in high-temperature Lardarello field in Tuscany in order to develop a temperature and pressure logging tool being able to withstand extreme temperature of 450°C, which is however much lower than temperatures actually recorded during drilling of the Venelle-2 well, and exposure to the operation time of minimum of 6 hours. The design of the mentioned tool is based on logging to an internal memory system technology and is powered by batteries resistant to ultra-high temperatures. Metal seals used in the tool are rated for 650°C and measurement accuracy is 5°C and 0.5 bars (Bertani et al. 2018).

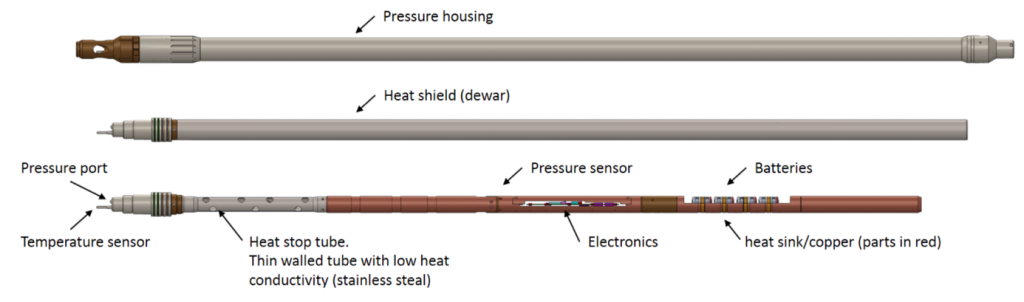

Fig. 1. Top: The logging tool with pressure housing. Temperature sensor and pressure port to the left (nose) and connection for the slickline wire to the right; Middle: Pressure shield and nose protector removed; Bottom: Heat shield removed. (Bertani et al. 2018).

Fig. 1. Top: The logging tool with pressure housing. Temperature sensor and pressure port to the left (nose) and connection for the slickline wire to the right; Middle: Pressure shield and nose protector removed; Bottom: Heat shield removed. (Bertani et al. 2018).

Additional temperature measurements were installed during the IDDP-2 campaign on the outside of the production casing string during running in operations. Installed at various depths between 341 and 2641 m eight thermocouples and a fiber optic cable, were expected to enable continuously measure strain, acoustic noise as well as record temperatures during drilling and potential future fluid production as well as to evaluate the quality of primary cementing operations of the production casing string. Thermocouples installed in the cement sheath of the production casing string within the IDDP-2 well ceased to transmit temperature data after short operation time, even though casing was not exposed to temperatures higher than 100°C. The condition of the fiber optic cable is yet not known, as it will be used after the IDDP-2 well is heated up (Friðleifsson et al. 2017a and 2017b).

Fig. 2. Installation of thermocouples and fiber optic cable on the outside of production casing within the IDDP-2 well (Friðleifsson et al. 2018)

Fig. 2. Installation of thermocouples and fiber optic cable on the outside of production casing within the IDDP-2 well (Friðleifsson et al. 2018)

Fig. 3. Thermocouples and fiber optic cable installed on the outside of production casing within the IDDP-2 well (Friðleifsson et al. 2018)

Fig. 3. Thermocouples and fiber optic cable installed on the outside of production casing within the IDDP-2 well (Friðleifsson et al. 2018)

For more #GeothermalFactsandStats check back weekly and follow us on all the major social media platforms.

References:

- Ásmundsson R, Pezard P, Sanjuan B, Henninges J, Deltombe J-L, Halladay N, Lebert F, Gadalia A, Millot R, Gibert B, Violay M, Reinsch T, Naisse J-M, Massiot C, Azaïs P, Mainprice D, Karytsas C, Johnston C. High-temperature instruments and methods developed for supercritical geothermal reservoir characterization and exploitation—The HiTI project. Geothermics. 2014; 49:90–8.

- Bertani R, Büsing H, Buske S, Dini A, Hjelstuen M, Luchini M, Manzella A, Nybo R, Rabbel W, Serniotti L. The first results of the Descramble project. In: Proceedings, 43rd workshop on geothermal reservoir engineering, Stanford University, Stanford, California, February 2018.

- Friðleifsson GÓ, Elders WA. Successful drilling for supercritical geothermal resources at Reykjanes SW Iceland. Trans Geotherm Resour Council. 2017; 41:1095–106 (a).

- Friðleifsson GÓ, Elders WA, Albertsson A. The concept of the Iceland Deep Drilling Project. Geothermics. 2014b; 49:2–8. Friðleifsson GÓ, Elders WA, Zierenberg RA, Stefánsson A, Fowler APG, Weisenberger TB, Harðarson BS, Mesfin KG. The Iceland Deep Drilling Project 4.5 km deep well, IDDP-2, in the sea-water recharged Reykjanes geothermal field in SW Iceland has successfully reached its supercritical target. Sci Drill. 2017; 23:1–12 (b).

- Friðleifsson GÓ, Albertsson A., Þórólfsson G., Sigurðsson Ó., Zierenberg RA, Elders W, Jóhannesson Þ, Óskarsson F, The IDDP-2 DEEPEGS Demonstrator at Reykjanes (PowerPoint presentation), 2018

Article based on a study by Kruszewski and Wittig titled “Review of failure modes in supercritical geothermal drilling projects” published in Geothermal Energy (2018) 6:28 (doi.org/10.1186/s40517-018-0113-4).